Hypochlorite generation is possible onsite and typically dosed into potable, process, reclaim, and wastewaters prior to distribution. This next generation of chlorination could be the answer you are looking for, capacities from 2 to 3,000+, these fully automated system work so you don’t have too. With our knowledge of on-site chlorine generation and control, we can help you eliminate the time, expense and associated hazards of maintaining chlorine inventories and safety requirements.

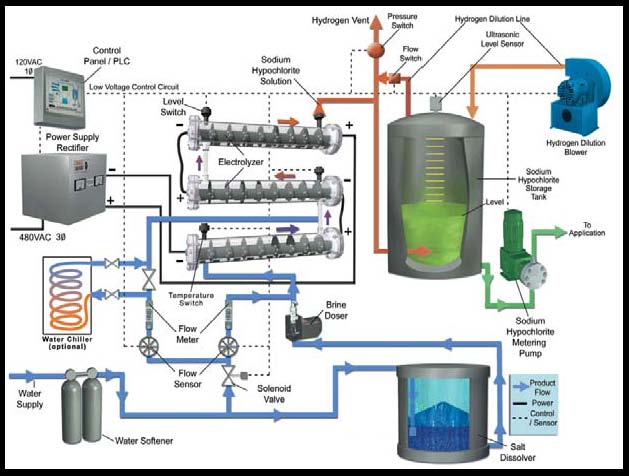

On‐site Sodium Hypochlorite Generation disinfection systems utilized water, salt, and electricity applied in solution to produce sodium hypochlorite. Incoming water typically goes first through a softener, then to a brine tank and electrolytic cell, near saturated brine is injected into the softened water just prior to the electrolytic cell, where electricity is applied and a current is passed through the solution in the electrolytic cell, resulting in sodium hypochlorite and hydrogen gas. The sodium hypochlorite being batch stored in a holding tank, then dosed into the process by the treatment control system, the hydrogen gas being a natural byproduct of the electrolytic process being safely removed from the cell and storage tank, diluted and exhausted to outdoors.

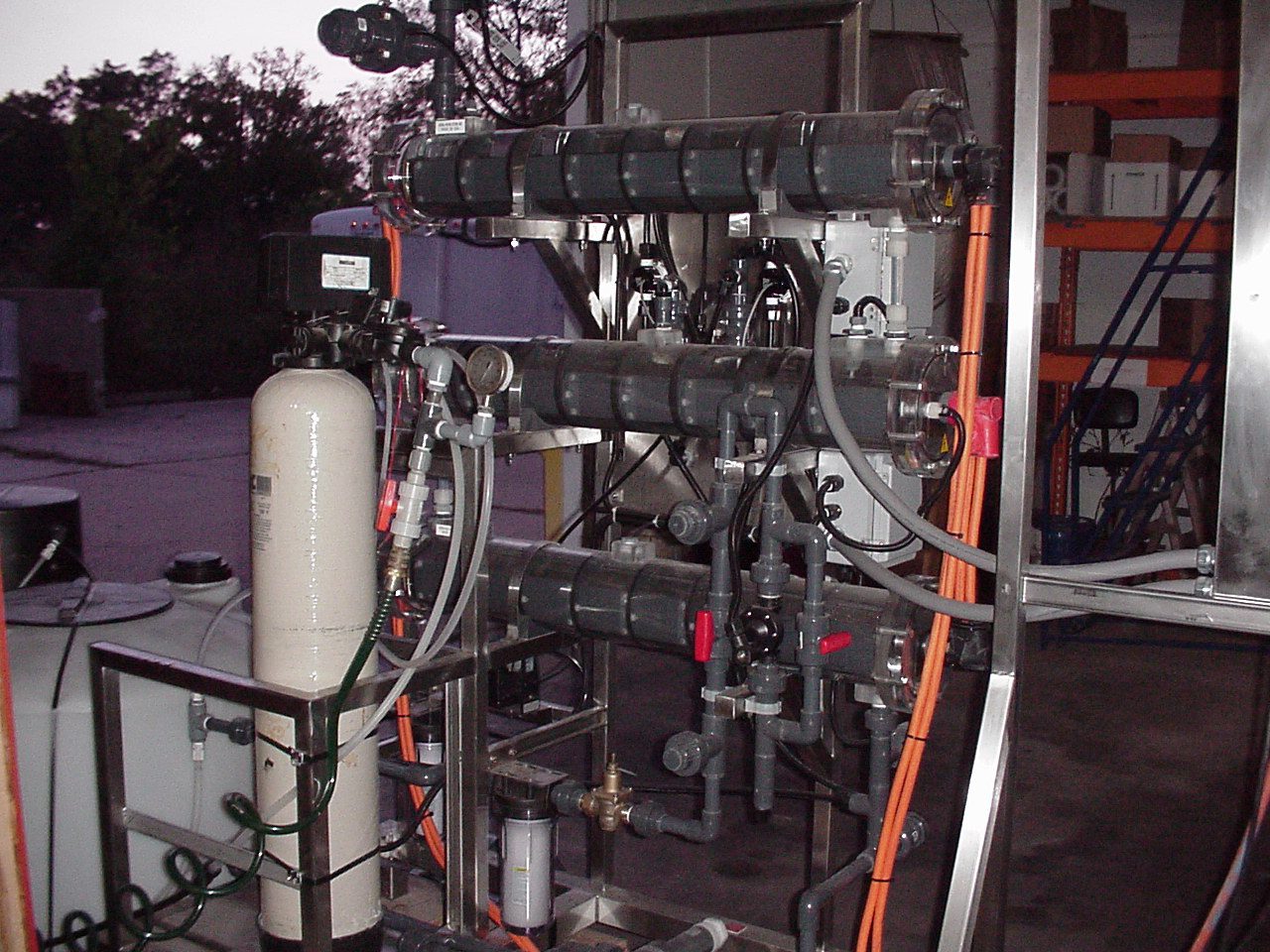

The next generation of chlorination could be the answer you are looking for, using only salt, water and electricity to produce chlorine capacities from 2 to 3,000+, these fully automated system work so you don’t have too. With our knowledge of on-site chlorine generation and control, we can help you eliminate the time, expense and associated hazards of maintaining chlorine inventories and safety requirements.