Thermal Hydraulic Audit

This unique service provides customers with an array of valuable information about their cooling water system. The service delivers three very important benefits:

- An evaluation of the cooling water distribution throughout the system relative to original design considerations.

- A process of evaluating the performance of each bundle over time.

- A method of planning turnaround exchanger lists in advance of the shutdown which can eliminate clean bundles, saving time and money. Insures the dirty bundles are opened and cleaned.

The information obtained from this service provides Design Controls valuable troubleshooting data that assists us in delivering the most meaningful studies.

Our Accuracy & Knowledge

- An average of 200-350 exchangers per man, per week

- This familiarity with the Panametrics flowmeters equates to accuracy

- It also means efficiency

Audit Overview

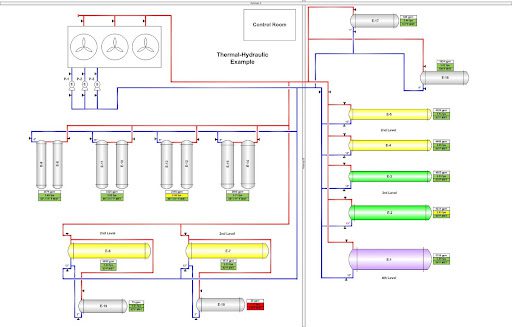

The Flow Team maps and sketches the entire Cooling Water System Flows and temperatures are obtained on all exchangers, coolers and condensers Exchanger data sheets are assembled for each exchanger so a comparison of design versus actual performance can be made.

Each Audit is prepared after each including:

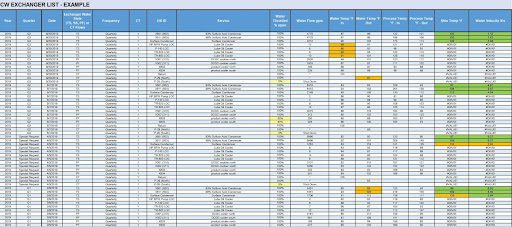

- Spreadsheet Deliverable

- Detailed Visio drawing of each CT and System

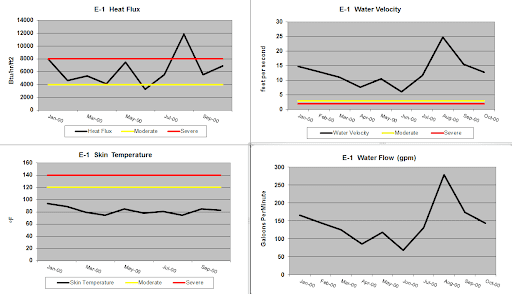

- Individual Exchanger Survey History

After subsequent routine visits are completed historical reports are constructed for each individual exchanger.

Tools of the Trade

System Plot Plan Example

Spreadsheet Data Example

We create a design and actual datasheet for the exchangers in the unit. Thorough design information allows us to calculate both design and actual performance metrics for each bundle, identifying stresses in each unit.

Individual Exchanger History

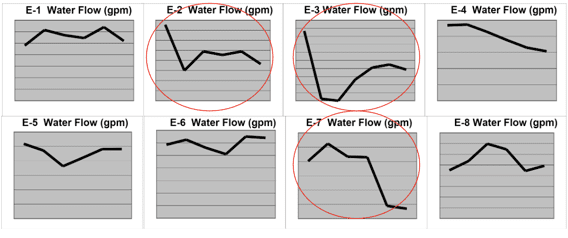

Historical performance data is used to create trends that can be helpful in identifying bundles for inclusion or exclusion on upcoming turnarounds.

Turnaround Planning

Benefits

- Design vs. Actual exchanger performance comparison indicating areas for potential improvement

- Allows optimization of available flow to insure proper cooling where most needed

- Identifies potential problem areas which could result in limited production or shortened reliability of equipment

- Potential increased profitability through improved exchanger performance

- Increased system knowledge with a comprehensive cooling system understanding

- Creates a ready reference for trouble shooting, and is a valuable training tool

- Provides a method of evaluating exchanger cleanliness before turnarounds, which could help identify which exchangers should be opened, eliminating those that are clean and potentially reducing overall costs and shortening down time